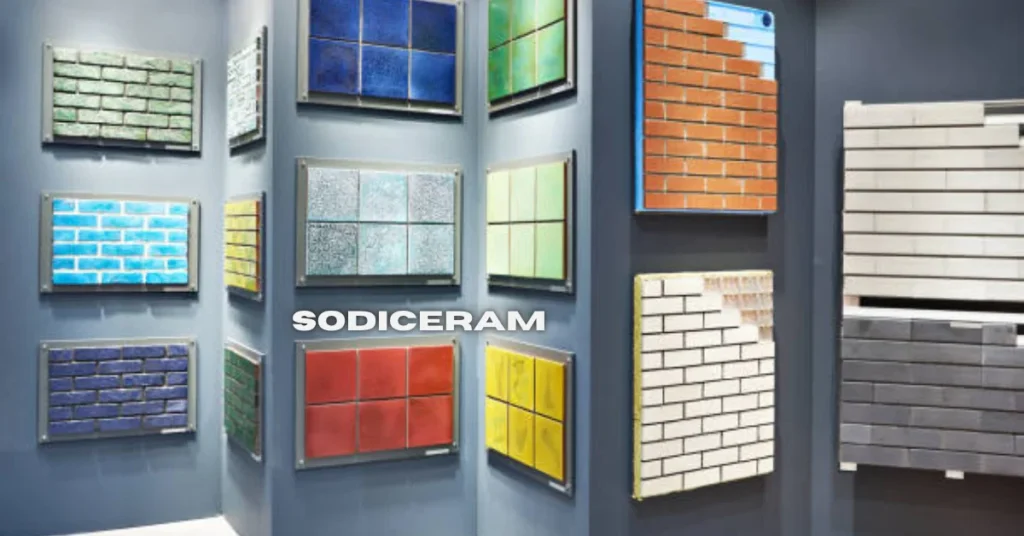

Welcome to the future of ceramic technology! If you think ceramics are just for dishes and tiles, think again. Sodiceram is revolutionizing how we perceive and utilize these materials across various industries. This innovative technology is not only enhancing performance but also paving the way for more sustainable solutions. Curious about what makes sodiceram stand out? Let’s dive into this exciting world where tradition meets innovation and discover why it’s poised to change everything we know about ceramics.

What is sodiceram?

Sodiceram is an advanced ceramic material that has gained attention for its unique properties and innovative applications. This cutting-edge technology combines traditional ceramic elements with modern enhancements, resulting in a product that offers superior performance.

Unlike conventional ceramics, sodiceram boasts improved durability and resistance to wear and tear. Its composition allows it to withstand extreme temperatures without losing integrity. This makes it suitable for various uses across industries.

Furthermore, sodiceram can be customized easily during production. Manufacturers appreciate the flexibility this provides when creating tailored solutions for specific needs.

With its combination of strength and versatility, sodiceram redefines what’s possible in ceramic technology. As industries evolve, so does the demand for materials like sodiceram that push boundaries beyond standard expectations.

The Benefits of Sodiceram over Traditional Ceramic Materials

Sodiceram stands out for its remarkable strength and durability compared to traditional ceramics. This advanced material can withstand higher temperatures and resist breaking under stress, making it ideal for demanding applications.

Another significant advantage is its lightweight nature. Users can enjoy the benefits of ceramic without the cumbersome weight often associated with conventional options.

Additionally, sodiceram offers superior thermal resistance. It maintains stability in extreme conditions, which enhances performance across various industries from aerospace to home goods.

The versatility of sodiceram also cannot be overlooked. It can be molded into complex shapes easily, opening up new design possibilities that traditional ceramics simply cannot match.

Moreover, because sodiceram is less porous than conventional materials, it provides better protection against stains and moisture damage. This quality not only prolongs product life but also makes maintenance a breeze for users.

Different Applications of Sodiceram in Various Industries

Sodiceram is making waves across various industries, showcasing its versatility and strength. In the construction sector, it serves as a durable alternative to traditional tiles and bricks. Its lightweight properties ease transportation while maintaining structural integrity.

The automotive industry benefits from sodiceram’s heat resistance and durability. Components made with this innovative material can endure extreme temperatures without compromising performance.

In electronics, sodiceram plays a crucial role in insulators and dielectric materials. Its efficient thermal conductivity enhances device functionality while minimizing energy loss.

Healthcare also sees advantages through sodiceram’s biocompatibility in medical devices. This allows for safer interactions within the human body.

Even in the art world, artists are exploring sodiceram for creating unique sculptures that challenge conventional design limits. Each application highlights how sodiceram is revolutionizing not just manufacturing but creative expression across multiple fields.

How Sodiceram is Changing the Game for Manufacturers and Consumers

Sodiceram is reshaping the landscape for both manufacturers and consumers alike. Its versatility allows for streamlined production processes, reducing waste and costs significantly. Manufacturers can create intricate designs more easily without compromising on durability or quality.

For consumers, this means access to innovative ceramic products that are not only aesthetically pleasing but also functional. Whether it’s in home décor or industrial applications, sodiceram offers enhanced performance characteristics that traditional ceramics simply can’t match.

Moreover, the lightweight nature of sodiceram enables easier handling during transportation and installation. This convenience translates into savings which ultimately benefit end-users.

As manufacturers adopt this technology, they’re discovering new possibilities in design and functionality. The shift towards sodiceram represents a significant advancement that caters to modern demands while pushing the boundaries of what ceramic materials can achieve.

Environmental Impact of Sodiceram

Sodiceram stands out for its remarkable eco-friendliness. Unlike traditional ceramics, which often rely on energy-intensive kilns and high-temperature processes, sodiceram minimizes carbon footprints through innovative manufacturing techniques.

The materials used in sodiceram are sourced sustainably. This reduces the environmental strain associated with extraction and processing. With a focus on recycling and reusability, it supports a circular economy model that traditional ceramics struggle to achieve.

Additionally, sodiceram’s durability means longer product lifespans. Fewer replacements translate to less waste filling landfills over time.

Water efficiency is another critical factor; production methods require significantly less water compared to conventional ceramic production methods. This is vital as global resources become strained.

In essence, by integrating sustainability into every facet of its design and creation process, sodiceram paves the way for environmentally responsible practices within the industry.

Potential Challenges and Future Developments for Sodiceram

Sodiceram, while promising, faces several challenges on its path to widespread adoption. One significant hurdle is the initial investment required for new manufacturing processes. Traditional facilities may need upgrades or complete overhauls to accommodate this innovative material.

Another challenge lies in market education. Many consumers and manufacturers are unfamiliar with sodiceram’s unique properties and benefits. Effective communication about these advantages is crucial for gaining traction.

Research continues to explore potential enhancements in performance and sustainability. Ongoing development could lead to even more versatile applications across different sectors.

Moreover, regulatory standards are evolving rapidly, which might pose a challenge as industries seek compliance with environmental guidelines while adopting sodiceram solutions.

Addressing these challenges will be key in solidifying sodiceram’s role as a leader in ceramic technology moving forward.

Why Sodiceram is the Future of Ceramic Technology

Sodiceram is redefining the landscape of ceramic technology. Its advanced formulations and techniques bring forth a new era, where traditional limitations fade away.

With unmatched durability and flexibility, sodiceram withstands extreme conditions without compromising aesthetics. This material excels in both performance and design.

The adaptability of sodiceram opens doors across industries—from aerospace to medical devices. Manufacturers can innovate freely, pushing boundaries previously thought impossible.

Furthermore, its lighter weight compared to conventional ceramics enhances efficiency in production and application. This means reduced energy costs during manufacturing processes.

Consumers benefit too; they receive products that are not only beautiful but also longer-lasting and more sustainable. The innovative spirit behind sodiceram signals a shift towards smarter solutions in everyday life.

As research continues, the potential for further advancements seems limitless, ensuring that sodiceram will remain at the forefront of ceramic innovation for years to come.

Conclusion

Sodiceram is carving out a niche in the world of ceramic technology, blending innovation with practicality. Its unique properties offer numerous advantages over traditional materials, making it an appealing choice for various industries. From construction to high-tech applications, sodiceram’s versatility and durability set it apart.

As manufacturers embrace this cutting-edge material, consumers also stand to benefit from enhanced products that meet modern demands. The environmental implications of sodiceram are promising as well, suggesting a more sustainable future in production methodologies.

While challenges remain—such as integration into existing manufacturing processes—the potential for further development is vast. Sodiceram represents not just an evolution but a revolution in how we think about ceramics.