Introduction to Leveling Casters

Leveling casters are critical components for industries and businesses requiring both the convenience of mobility and the assurance of a stable, fixed position. By combining the features of a caster with those of an adjustable leveling foot, leveling casters allow users to move equipment effortlessly, then stabilize it securely—regardless of the floor’s condition. This flexibility is especially valuable in dynamic environments where workspace layout changes are frequent or equipment must remain unwaveringly steady once in place.

Unlike traditional casters, which offer rolling convenience at the cost of stability, leveling casters deliver both. They enable users to roll heavy machinery or lab equipment to a new location and adjust each caster’s height to create a perfectly level surface. Their ability to address uneven flooring and create a stable base makes them essential for a multitude of professional settings.

Design and Functionality

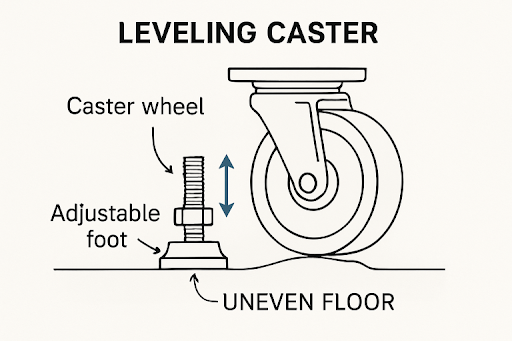

At the heart of every leveling caster is a smart design that integrates a wheel and an adjustable foot into a single compact unit. The foot, controlled by a threaded stem or screw mechanism, can be manually raised or lowered to compensate for surface irregularities. This ensures that equipment remains stationary, even under load or during sensitive operations.

Moreover, many leveling casters feature a robust locking mechanism that securely locks the adjusted position. While the caster allows smooth movement and swiveling, the leveling foot can be deployed to keep machinery or furniture fixed and safe, illustrating how these components truly provide the best of both worlds.

The materials used in constructing leveling casters are crucial to ensuring longevity and performance. Manufacturers commonly utilize:

- Stainless Steel: Chosen for environments demanding sterility and corrosion resistance—such as medical facilities and cleanrooms—stainless steel provides robust protection and easy cleaning.

- Nylon: Nylon casters are recognized for their durability and lightweight nature. They are suitable for industrial and commercial settings and provide resistance to frequent wear.

- Rubber: Offering cushioning and vibration dampening, rubber wheels protect delicate floors and offer smooth rolling over irregular surfaces.

- Phenolic: Withstanding high temperatures and heavy weights, phenolic casters are the choice for heat-intensive industrial environments.

- Matching caster material to the expected operating environment is essential to guarantee both function and floor protection.

Applications Across Industries

Leveling casters serve a vital role across diverse industries, thanks to their adaptability and support for varying operational demands:

- Manufacturing: Assembly lines and heavy manufacturing equipment rely on these casters for precise, stable positioning that withstands repetitive motion.

- Healthcare: Devices ranging from hospital beds to diagnostic carts benefit from reliable movement and patient-safe stability.

- Laboratories: Lab benches, microscopes, and sensitive testing gear require unwavering stability for experiments and measurements.

- Retail: Movable shelving units, displays, and cash wraps benefit from flexibility and a secure, level platform for daily operations.

With such broad utility, it’s no surprise that leveling casters have become standard in workplaces where safety and flexibility are priorities. Further information on mobility and workplace safety can be found at the Occupational Safety and Health Administration (OSHA), which outlines industry standards that integrating casters can help address.

Benefits of Using Leveling Casters

- Enhanced Stability: These casters offer a secure, level base during use, mitigating the risk of equipment shifting or tipping—vital in precision-driven tasks.

- Improved Safety: Leveling casters protect operators and improve procedural accuracy by limiting vibration and unwanted movement.

- Increased Productivity: Mobility and straightforward stabilization allow teams to adapt workspaces for efficiency and evolving needs swiftly.

- Cost-Effectiveness: Organizations reduce costs by using dual-purpose casters rather than purchasing separate part assemblies for mobility and stabilization.

Choosing the Right Leveling Caster

Businesses must weigh several factors when selecting leveling casters for specific applications:

- Weight Capacity: The caster’s load rating should comfortably exceed the maximum expected equipment weight to uphold stability and prevent failures.

- Mounting Type: Plate and stem mounting types offer options based on how the caster will attach to the equipment. Compatibility with frame design is essential.

- Wheel Material: Choosing wheel materials suited to flooring types and operating environments helps safeguard longevity and functional efficiency.

Installation and Maintenance

- Installation: Begin by securely affixing the caster to the base of the equipment with proper mounting hardware, adhering to manufacturer specifications.

- Adjustment: After moving equipment into position, adjust the caster’s foot to stabilize and balance the platform perfectly, verifying levelness as needed.

- Maintenance: Schedule regular inspections, look for wear signs, and lubricate swivel or threaded components. To prevent operational interruptions, replace damaged or worn-out casters without delay.

Final Thoughts

Leveling casters are indispensable assets wherever equipment mobility and safe operation are essential. Their dual-action design—rolling flexibility and steadfast stability—supports safer, more productive workflows across manufacturing, healthcare, laboratories, and retail sectors. Choosing the right caster for your needs and maintaining it properly enhances operational efficiency and extends the life of your valuable equipment. By understanding the functionality and selecting the best options, organizations position themselves for reliability and greater workplace safety.